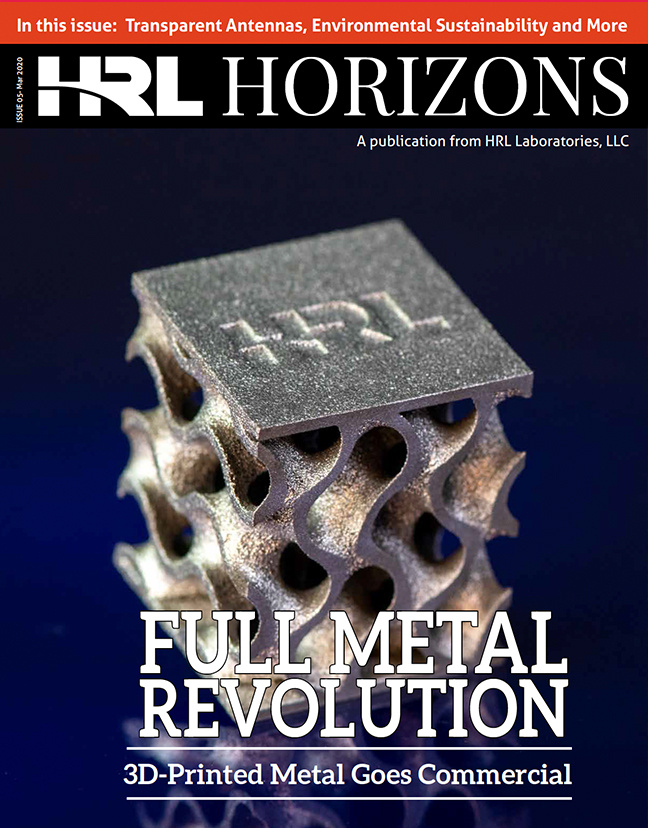

3D Printing of Metal Matrix Composites Opens World of New Design Possibilities

Setting another new milestone in metallurgy, scientists from HRL Laboratories have used their breakthrough process to 3D print metal matrix composite (MMC) parts utilizing a new nanofunctionalization process. 3D printing of MMCs enables geometric freedom in design for parts made of these materials that were not possible before. In their research study, the HRL Team printed an MMC that was 20% stronger and two times more durable based on wear characteristics than the baseline alloy without the other elements added.

Metal matrix composites are materials resultant when a baseline alloy is combined with another metal or with ceramic or organic compounds. The final MMC has unique properties contributed by each constituent material, making them desirable for specialized, high-performance applications such as brake disks and turbine blades.

Although 3D printing, or additive manufacturing, enables parts to be made accurately with very complex geometries, little research has been done on ways to additively manufacture MMCs. HRL’s nanofunctionalization method of seeding feedstock with nanoparticles to control solidification enables MMCs of any combination of elements to be printed on any appropriate additive manufacturing equipment. This material-agnostic and equipment-agnostic printability opens a completely new avenue of geometric design to these sought-after materials.

“For our paper we used one specific alloy,” said first author Hunter Martin. “However, our nanofunctionalization approach now has been proved to be viable for MMCs. This means it could be used on other systems with different base alloy constituents and nanoparticles to 3D print parts made of existing MMCs, as well as trying new MMCs.”

The study was published online on May 22 in the journal MRS Communications. Martin’s co-authors were Brennan Yahata, Eric Clough, Justin Mayer, Jacob Hundley, and Tobias Schaedler.

HRL Laboratories, LLC, Malibu, California (hrl.com) is a corporate research-and-development laboratory owned by The Boeing Company and General Motors specializing in research into sensors and materials, information and systems sciences, applied electromagnetics, and microelectronics. HRL provides custom research and development and performs additional R&D contract services for its LLC member companies, the U.S. government, and other commercial companies.

Media Inquiries: media[at]hrl.com, (310) 317-5000