Aligning Nanoparticles to Create Dense Materials

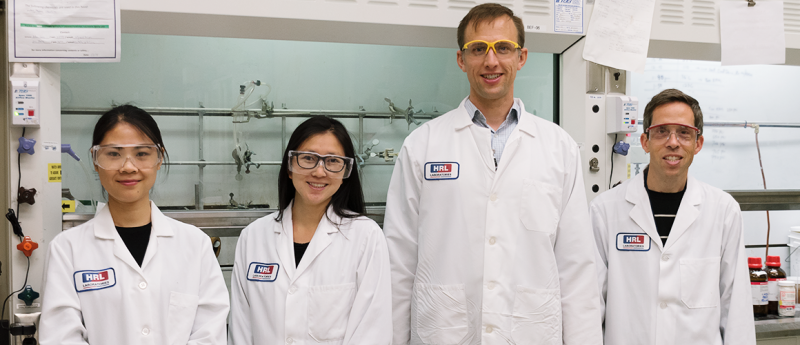

L to R: Xin Guan, Shanying Cui, Chris Roper, Adam Gross. © 2018 HRL Laboratories.

New Manufacturing Method Can Build Dense Microstructures From Difficult Materials In Water Solution With Low Cost and High Safety

HRL Laboratories, LLC, researchers have successfully demonstrated a scalable, water-based nanoassembly manufacturing technique with many possible uses, including growing powerful rare-earth-free magnets and infrared optical materials.

Using a model system, the HRL team demonstrated alignment and stacking of iron oxyhydroxide (FeOOH) nanorods and assembly of lithium yttrium fluoride (LiYF4) nanoparticles into dense micron-scale structures in a versatile method that is faster than current material assembly techniques, without the need for organic chemicals or solvents. The new method is a bench-top task and is scalable to industrial manufacturing volumes.

We’ve shown a way to do nanotechnology up to the micron scale using water and a benchtop apparatus, in a scalable and fast manner.

The FeOOH nanorods were 150 nanometers long and 50 nanometers in diameter or approximately 1/1,500ththe width of a human hair. More than 10 million (107) individual aligned nanorods self-assembled into structures called microarrays that were 50-80 microns in diameter (a human hair is 60-100 microns thick).

Artist’s concept of loose FeOOH nanorods self- assembling after lowered pH affects electrostatic surface charge. © 2018 HRL Laboratories.

“The assembly is achieved by adjusting the pH in water containing the nanoparticles and thus changing the nanorod’s surface charge. Decreasing electrostatic repulsion draws the nanoparticles to self-assemble into tightly aligned micron-scale structures,” said Shanying Cui, HRL’s first author on the paper. “Our technique is also generalizable to many other useful nanomaterials that have pH-dependent surface charges.”

“This novel approach to microassembly will enable us to build dense microstructures with materials that normally are very difficult to manipulate without using organic solvents or surfactants,” said senior author Adam Gross. “One example for which this is advantageous is magnetic materials. Increased density and alignment of domains in a magnet increase its energy product, which is the general measurement of magnet quality. A microassembly technique that packs magnetic nanoparticles more densely enables a magnetic structure with a higher energy product. This technique could allow us to make stronger magnets for motors without using rare earth materials if we assembled different nanoparticles.”

The LiYF4nanoparticles are approximately the same size as the FeOOH nanorods, but have a tetragonal bipyramid structure (two four-sided triangles joined at the base). LiYF4is an upconverting optical material that is transparent over a wide spectral window and can interact with light with wavelengths from 0.15 to 7.5 mm if no infrared absorbing ligands are present. This additional demonstration shows that HRL’s assembly technique applies to optical materials as well as multiple nanocrystals shapes, thus broadening its applicability.

“With this paper we showed how to go from single nanoparticles with unique properties to a material that a person can interact with and see with the naked eye,” said co-author Chris Roper. “We’ve shown a way to do nanotechnology up to the micron scale using water and a benchtop apparatus, in a scalable and fast manner”

“This method is also applicable to optically active insulators such as oxides and fluorides, and semiconductors such as metal sulfides and metal phosphides,” Gross said. “Being able to work in water improves the scalability of the whole process.”

The paper, entitled Aqueous assembly of oxide and fluoride nanoparticles into 3D microassemblies, was published in the June, 2018 issue of Langmuir, the American Chemical Society journal of fundamental interface science.

HRL Laboratories, LLC, Malibu, California (hrl.com) is a corporate research-and-development laboratory owned by The Boeing Company and General Motors specializing in research into sensors and materials, information and systems sciences, applied electromagnetics, and microelectronics. HRL provides custom research and development and performs additional R&D contract services for its LLC member companies, the U.S. government, and other commercial companies.

Media Inquiries: media[at]hrl.com, (310) 317-5000