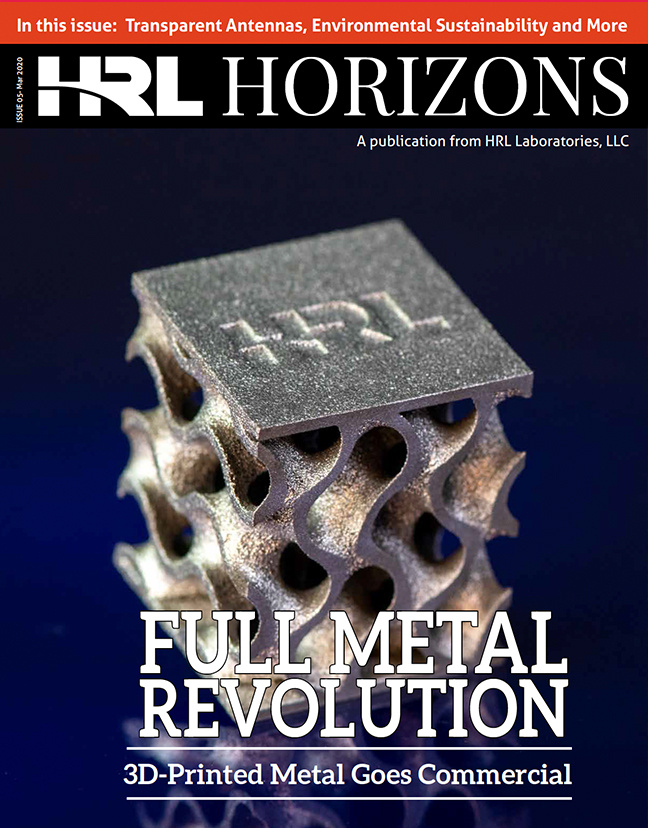

HRL Announces Extraordinary New Lightweight Materials

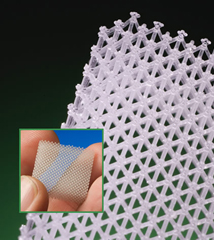

New lightweight materials have been created by rapidly forming tiny three-dimensional truss-like patterns. © HRL Laboratories.

Amazing new materials that could spawn an entire generation of lightweight technologies have been generated by HRL Laboratories, LLC in collaboration with the University of Southern California’s Composites Center. Micro-architected materials produced at HRL show considerable promise for enabling lighter-weight vehicles with higher performance, such as automobiles with greater fuel efficiency, longer range aircraft and rotorcraft, and increased capacity launch vehicles and space systems.

But this is just the beginning. By changing the overall pattern of the optical processing used to create these materials and the material composition, the researchers say, you can change the applications to medicine, such as stronger, biocompatible tissue scaffolding, bone implants or skin grafts. Change the pattern and the material composition again, and you can create improved current collectors for batteries and cooling architectures for high-power electronics.

The technique developed at HRL exploits the micro-scale to make remarkably stiff, strong, and most of all, lightweight, material structures. At the core are three-dimensional truss-like (as in bridge support) patterns, fashioned via a unique research approach that criss-crosses polymer optical fibers on the micrometer level. With further improvements in the process and materials choice, the micro-scale structural properties could easily exceed those of current engineering materials such as steel or aluminum alloys.

As described in their recent article in Advanced Materials “Micro-scale truss structures formed from self-propagating photo-polymer waveguides,” and a subsequent article in Acta Materialia, HRL and USC researchers take advantage of a phenomenon used in forming polymer optical waveguides as the basis for their scalable, three-dimensional process. Polymer waveguides are optical fibers that can be formed in seconds from a single point exposure of light in an appropriate photo-sensitive substance. The researchers showed that simultaneously forming a three-dimensional interconnected pattern of waveguides results in a polymer structure with micrometer-sized truss features.

Unlike typical foam materials that are soft and flexible because of their random cellular structure, these new materials maximize mechanical stiffness and strength. While the initial structures are polymers, subsequent processing can transform them into a wide variety of metals, ceramics or composites with properties tailored to a given application.

HRL Laboratories, LLC, Malibu, California (hrl.com) is a corporate research-and-development laboratory owned by The Boeing Company and General Motors specializing in research into sensors and materials, information and systems sciences, applied electromagnetics, and microelectronics. HRL provides custom research and development and performs additional R&D contract services for its LLC member companies, the U.S. government, and other commercial companies.

Media Inquiries: media[at]hrl.com, (310) 317-5000