HRL Laboratories Selected for NOM4D Project to Develop Space-Based Construction Technologies

DARPA Program Aims to Revolutionize Large Space Structures by Developing New Techniques for on Orbit Manufacturing

MALIBU, Calif. January 11, 2023— HRL Laboratories, LLC, has been selected as one of eight industry and university research teams for the Novel Orbital Moon Manufacturing, Materials, and Mass Efficient Design (NOM4D) program from the Defense Advanced Research Project Agency (DARPA).

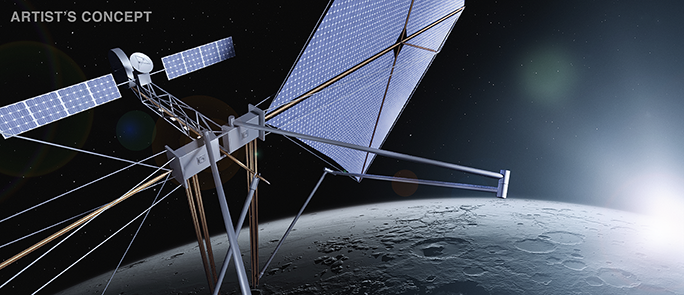

HRL’s Hydriform on-orbit manufacturing concept of a space power station. Concept art: John Carpenter. Copyright 2023 HRL Laboratories

The NOM4D program seeks to create a disruptive change in the way future space structures, such as orbital power stations or large radio frequency (RF) apertures with 100 meter diameter, are made. If successful, the extremely low energy structural forming and joining techniques developed under this program will enable much larger, more efficient structures than are possible today.

To do this, NOM4D teams are tasked with foundational proofs of concept in materials science, manufacturing, and design technologies. These prototype structures will show a path to overcome the size constraint of launch vehicle fairings and limited in-orbit power for forming and joining of large space structures.

Current large space structures, such as the James Webb Space Telescope, rely on deployable technology – mechanized structures that can fold, roll, or inflate – that are stowed prior to launch in a compact package and then deployed after launch to full size. “By forming materials to their final shape in space, we dispense with added structural mass needed to meet launch requirements,” said Dr. Christopher Henry, HRL’s Principal Investigator on NOM4D.

“HRL’s HYDRIde Forming for ORbital Manufacturing (HYDRIFORM) approach leverages HRL’s multi-disciplinary capabilities, together with our team L’Garde Inc. and ALLVAR, to develop a novel in space manufacturing concept that is both size and power efficient for fabrication yet pushes the bounds of efficient space structures,” said Dr. Henry.

HRL will demonstrate the key elements to achieve structures that can be built up from energy efficient structural members that are both formed and joined in space. These elements are: mass and power efficient forming of metallic members; and joining of metallic members in a lightweight, yet durable manner. “Both of these assembly operations have not really been explored previously and would form the basis for the ability to manufacture an arbitrarily large spacecraft structure,” adds Brian Hempe, HRL’s Lead Development Engineer.

“Our effort is focused on building the materials and manufacturing technologies required to enable this vision. It will form the basis for later flight experiments that will test our ability to realize precise, large structures in orbit,” said Dr. Henry.

Acknowledgement:

This material is based upon work supported by the Defense Advanced Research Projects Agency (DARPA) under Contract No. HR001122C0016. Any opinions, findings and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the Defense Advanced Research Projects Agency (DARPA).

HRL Laboratories, LLC, California (hrl.com) pioneers the next frontiers of physical and information science. Delivering transformative technologies in automotive,aerospace and defense, HRL advances the critical missions of its customers. As a private company owned jointly by Boeing and GM, HRL is a source of innovations that advance the state of the art in profound and far-reaching ways.

Media Inquiries: media[at]hrl.com, (310) 317-5000