HRL and Microsoft Researchers Team Up To Create Advanced Camera with a Highly Curved Image Sensor

HRL Laboratories, LLC, announced the successful results of research initiated and supported by Microsoft Research to create a prototype curved-sensor camera that surpasses the sharpness performance of larger professional camera systems, while also improving image uniformity and illumination. This research may provide very compact cameras with excellent performance in low light. The results were published on May 31st in Optics Express, a peer-reviewed journal of the Optical Society (OSA), the leading professional association in optics and photonics.

“Microsoft is constantly exploring new discriminating technology for their electronics products. They recognized limitations in existing camera modules, and developed a concept for a camera that used a curved image sensor. Their initial sizing and performance calculations demonstrated that unprecedented performance could be achieved with the curved sensor,” said HRL researcher Geoff McKnight. “Benefits would include increased sensitivity, full-field resolution, and reduced packaging weight and volume. Their internal research determined that one key technology element missing from this approach was a practical, cost-effective method for creating high-performance curved substrates using state-of-the-art silicon CMOS image sensors.”

“Microsoft is constantly exploring new discriminating technology for their electronics products. They recognized limitations in existing camera modules, and developed a concept for a camera that used a curved image sensor. Their initial sizing and performance calculations demonstrated that unprecedented performance could be achieved with the curved sensor,” said HRL researcher Geoff McKnight. “Benefits would include increased sensitivity, full-field resolution, and reduced packaging weight and volume. Their internal research determined that one key technology element missing from this approach was a practical, cost-effective method for creating high-performance curved substrates using state-of-the-art silicon CMOS image sensors.”

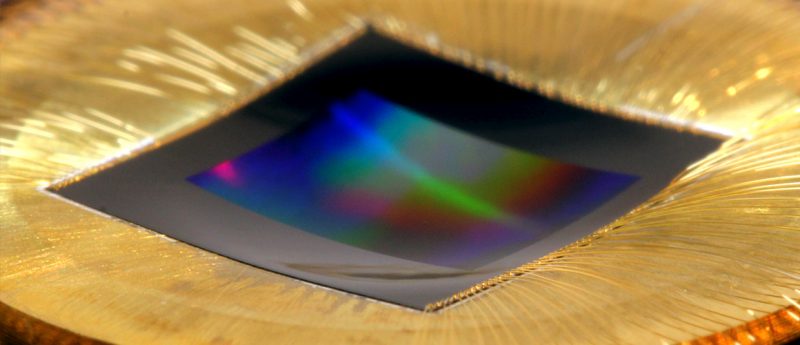

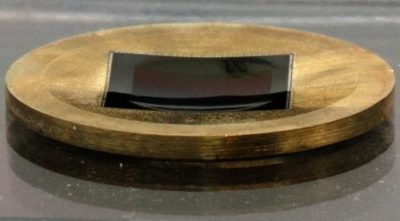

Given HRL Laboratories’ extensive experience in electronics fabrication and integration, Microsoft teamed up with HRL to help develop a process to reliably curve image sensors. Microsoft and HRL collaborated on an innovative, low-cost process that transforms current state-of-the-art flat sensor dies from high-volume silicon foundries into highly curved sensors. The bending process was developed over multiple years during the Microsoft-sponsored project. The final results are the culmination of extensive experimentation and finite element simulations that optimized many of the process and hardware parameters to maximize the sensor curvature while protecting the fragile silicon die. The key innovation was using pneumatic pressure combined with a system of weak boundary constraints to curve the sensor and maintain the curvature.

Matching one of the prototype smartphone-sized 18 megapixel curved sensors to a lens specially designed to take advantage of the curvature, the team measured image sharpness that significantly outperformed a large-format 35mm professional camera and lens system. While many issues remain to bring this technology to mass production, these initial results show dramatic potential for new cameras. Curved sensor technology is poised to improve many optic-related scientific fields including photography, videography, computer vision and automation, reconnaissance and surveillance imaging, microscopy, and telescopy, among others.

“With this technology, a whole new class of lenses can be created that weren’t possible before,” McKnight said. “The Microsoft/HRL process can be applied to virtually any existing image sensor, so there is no costly redesign or new material development required.” Microsoft researchers on the paper included Neel Joshi, Brian Guenter, and Rich Stoakley. HRL researchers on the paper included Andrew Keefe, Kevin Geary, Ryan Freeman, Jake Hundley, Pamela Patterson, David Hammon, Guillermo Herrera, Elena Sherman, Andrew Nowak, Randall Schubert, Peter Brewer, Luis Yang, and Russell Mott.

HRL Laboratories, LLC, California (hrl.com) pioneers the next frontiers of physical and information science. Delivering transformative technologies in automotive,aerospace and defense, HRL advances the critical missions of its customers. As a private company owned jointly by Boeing and GM, HRL is a source of innovations that advance the state of the art in profound and far-reaching ways.

Media Inquiries: media[at]hrl.com, (310) 317-5000