Aiming to Improve Infrared Cameras by Curving Focal Plane Arrays

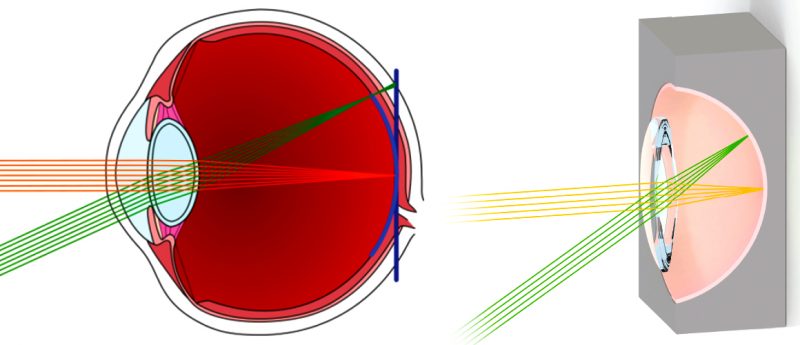

HRL engineers hope that curving the detector of an infrared camera will allow access to desirable traits common to the evolutionarily convergent ‘camera-type’ eyes, with their characteristic bowl-shaped retinas: a wide field of view, low aberrations, and simple optics. © 2020 HRL Laboratories.

HRL Laboratories Launches Two DARPA-Sponsored Infrared Sensor Projects

HRL Laboratories, LLC, scientists and engineers are taking on the challenge of developing sensors that are doubly-curved, like a bowl, under a new program from the Defense Advanced Research Project Agency (DARPA) sighted on the advancement of infrared (IR) vision. Two distinct awards under DARPA’s FOcal arrays for Curved Infrared Imagers (FOCII) program are endeavoring to create curved IR focal plane arrays (FPAs) by applying expertise gained from successfully curving photographic sensors in visible-light cameras (Optics Express: Vol. 25, Issue 12, pp. 13010-13023, 2017).

A curved photographic sensor enhances clarity throughout an image by bringing its corners into focus and brightness that are equal to the center of the image. A camera constructed with a spherical lens surrounded by a bowl-shaped sensor could see all directions in a 180-degree range at once with perfect focus – something that is not possible with flat sensors. Improved image quality at extreme angles of incidence can be important when cameras and sensors are used for situational awareness applications, where, for example, any potential obstacles surrounding a vehicle or soldier need to be identified and tracked.

The project Strain Engineering Approach to Manipulating Large Infrared Sensor Shaping (SEAMLISS) “aims to develop a process and toolset to enable any existing midwave or longwave IR FPA to be curved up to a 50-degree subtended angle,” said HRL’s SEAMLISS Principal Investigator, Dr. Mark O’Masta. “If successful, this would allow us to use the highest performance and largest format FPAs available on the market and curve them to be concave like a human retina. The benefit in developing this new technology will be in allowing construction of simple, compact, and high-performance optical designs.”

For the second project, HRL seeks to design and fabricate smaller infrared sensors with more extreme, nearly hemispherical curvature. “HRL hopes to fabricate a bowl-shaped FPA enabled through our pioneering 3D-printing technology combined with methods to pattern and bend semiconductor sensor dies to accept hemispherical curvature.” said Dr. Tobias Schaedler, Principal Investigator of this effort. “The advantage of this would be that an infrared detector with a more extreme radius should enable high-performance sensors with a wider field of view.”

HRL Laboratories, LLC, California (hrl.com) pioneers the next frontiers of physical and information science. Delivering transformative technologies in automotive,aerospace and defense, HRL advances the critical missions of its customers. As a private company owned jointly by Boeing and GM, HRL is a source of innovations that advance the state of the art in profound and far-reaching ways.

Media Inquiries: media[at]hrl.com, (310) 317-5000