HRL Advances to Camera-Build Phase of Curved Sensor Technology

Curved infrared imaging sensors take aim at wide field-of-view imaging

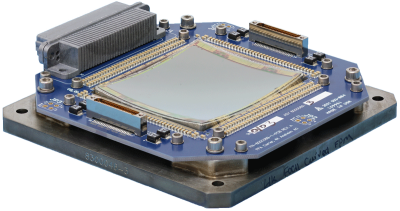

HRL Laboratories is developing spherically-curved infrared sensors that will be used in a future, first-of-its-kind camera build that will showcase the technology and highlight key benefits such as enhanced imaging capability and reduced camera size. Copyright 2024 HRL Laboratories

MALIBU, Calif. March 11, 2024— HRL Laboratories, LLC, has successfully reached a key milestone in developing sensors that are spherically-curved, under a program aiming to advance infrared (IR) vision funded by the Defense Advanced Research Project Agency (DARPA). Now, HRL will undertake Phase 3 of DARPA’s program, called FOcal arrays for Curved Infrared Imagers (FOCII). In a first-of-its-kind hardware demonstration, HRL intends to build an ambitious test camera that will showcase the newly curved sensor technology and highlight key benefits such as enhanced imaging capability and reduced camera size.

HRL entered new territory with the successful operation of its large-format infrared (IR) sensor with curvature well beyond published limits. HRL has been a pioneer in creating large-format focal plane arrays that offer extreme sensitivity to IR light with fast response times. As these state-of-the-art sensors are flat, HRL has developed a process to mechanically shape the sensors to achieve the curved state. Before attempting to curve full focal plane arrays, the research team performed early tests by curving flat diode test chips. These tests showed that the III-V detector materials, sensitive to midwave IR light, could withstand the large mechanical strains induced by curving, without degradation in key imaging performance attributes, including dark current and cutoff wavelengths [1]. The researchers also validated the ability of the sensors to withstand cryogenic temperature cycling, as the devices must operate at cold temperatures to achieve their high-end performance. With the operability of a curved infrared imager, Phase 3 will focus on building a camera and incorporating an extremely curved midwave IR sensor with a custom optical assembly from Sandia National Laboratories.

This work extends HRL’s previous success in curving visible light sensors [2]. A curved photographic sensor significantly widens the optics design space permitting advanced designs with dramatic improvements in brightness uniformity and edge-to-edge sharpness. In an extreme implementation, a camera constructed with a spherical lens surrounded by a spherically-shaped sensor could see all directions in a 180-degree field of view at once with excellent focus and low distortion. Improved image quality at extreme angles of incidence is important when cameras and sensors are used for situational awareness applications, where, for example, any potential obstacles surrounding a vehicle or soldier need to be identified and tracked. Furthermore, curving the image sensor enables the use of much shorter optics, which is a key design parameter for military and commercial products, such as future handheld equipment.

“This program is providing the opportunity to finally answer the question as to whether the considerable theoretical benefits of a curved image sensor for wide field of view imaging can be realized in practice for this extreme case of a very large and infrared sensor that must operate at cryogenic temperatures,” said Dr. Mark O’Masta, principal investigator for HRL’s project. “There have been considerable challenges from mechanical to thermal to electronic, but it’s incredible what the team has been able to accomplish.”

[1] O’Masta, M.R., et al. “Curving of Large-Format Infrared Sensors.” In Infrared Technology and Applications XLVIII, 12107:429–35. SPIE, 2022. https://doi.org/10.1117/12.2618122.

[2] Guenter, B., et al. “Highly Curved Image Sensors: A Practical Approach for Improved Optical Performance.” Optics Express 25, no. 12 (June 12, 2017): 13010–23. https://doi.org/10.1364/OE.25.013010.

This material is based upon work supported by the Defense Advanced Research Projects Agency (DARPA) under Contract No. N66001-20-C-4011. Any opinions, findings and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the DARPA.

HRL Laboratories, LLC, California (hrl.com) pioneers the next frontiers of physical and information science. Delivering transformative technologies in automotive,aerospace and defense, HRL advances the critical missions of its customers. As a private company owned jointly by Boeing and GM, HRL is a source of innovations that advance the state of the art in profound and far-reaching ways.

Media Inquiries: media[at]hrl.com, (310) 317-5000